September 26, 2023

LinkedIn Poll Results: Thoughts From Senior Director of 4C Supply®

Written by: Michael Carnes

4G Clinical recently ran survey polls to clinical supply professionals to collect feedback on drug supply forecasting through our LinkedIn account. We interviewed our Senior Director of 4C Supply®, Michael Carnes, to get his thoughts on and reactions to the results:

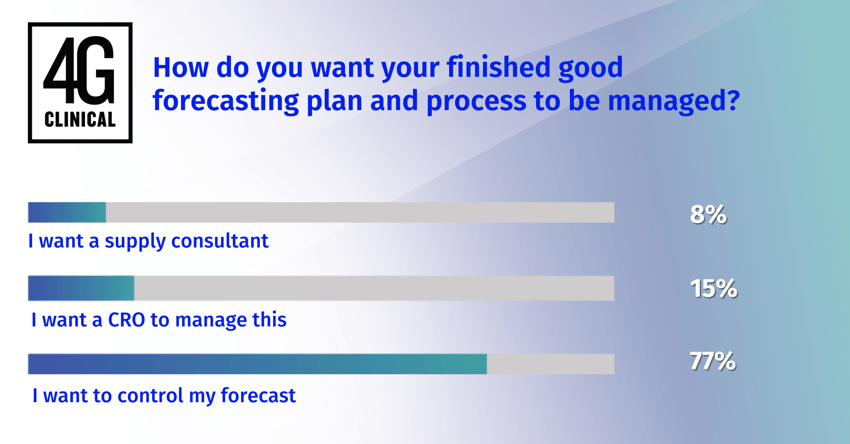

Does it surprise you that clinical supply professionals want control over their drug forecasting plan and overall process?

No, it does not surprise me. Clinical supply managers have a difficult job and are placed under immense pressure to ensure no patients are lost to stock outs while simultaneously controlling costs. Blindly following somebody else’s plan is too risky.

What specific features/functionality does 4C Supply® offer to put the power directly into the hands of clinical supply professionals to control their own drug forecasts?

4C Supply® was designed from the start to enable easy forecasting by entering a handful of parameters. Users can start simple in pre-clinical stages and then gradually expand complexity as greater detail is known about the network, material availability, and patient enrollment. Once a trial is underway, it is easy to pull in actuals and run multiple scenarios to adapt plans based on empirical evidence.

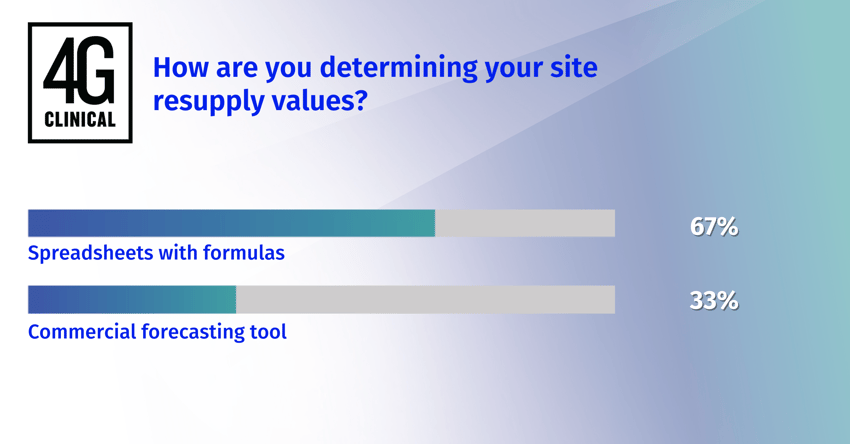

In your experience, is it still common throughout the industry to use manual spreadsheets for creating and tracking site resupply values for clinical trials? If so, what are some of the reasons behind this?

It is still common to use spreadsheets, and I don’t expect that to change. Spreadsheets are cheap and easy and there will always be a place for them particularly for earlier stage trials. However, spreadsheets carry risks. I come from an auditing background where we regularly saw people make huge mistakes with their calculations. This is even more problematic in multi-user environments where one person is trying to update a spreadsheet someone else made. And as trials grow in complexity, spreadsheets fall short in terms of modeling supply complexities such as global resupply.

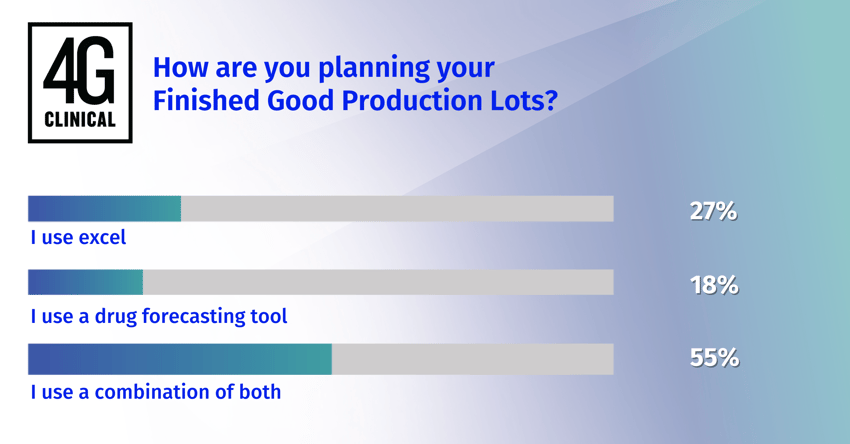

We have seen that many clinical supply professionals use a combination of both commercial tools and excel spreadsheets to manage their finished good production lots. In your opinion, does this revolve around a lack of trust in commercial forecasting tools, the need to ‘spot-check’ the final forecast or a combination of both?

In my experience planned lots are being managed in ERPs or MRPs. Short of building custom integrations, I think many people use spreadsheets to work with the demand data and create drug production quantities based on data that is coming out of their forecasting tools. With 4C Supply® we made it is easy to build planned lots that can be exported and used in your ERP, and to also reverse the process and bring planned lots into 4C Supply® and use its error checking and forecasting capabilities to ensure there isn’t risk of undersupply and stockouts based on what is planned to be produced.